Motor Bearing Lubricants

Developed on high quality base oils, BECHEM’s range of textile mill motor bearing greases possess excellent oxidation stability and ensures long term lubrication.

Motor bearing experience high radial and low axial loads during their operation, however the loads could be fluctuating owing to the motor being frequently switched on and off. High temperature (upto 80 °C) and excessive vibration are some other aspects that needs to be considered whilst selecting the right lubricant. High vibration can lead to the grease loosing consistency and oozing out of the applied area and eventual bearing failure.

Developed on high quality base oils, BECHEM’s range of textile mill motor bearing greases possess excellent oxidation stability and ensures long term lubrication. The speciality range of textile mill motor bearing grease can withstand high temperatures and provide consistent lubrication to the friction partners in spite of high vibration.

BECHEM’s range of motor bearing greases

Beruplex HTA is a high temperature multipurpose grease for extended lubrication of plain and roller bearings that are subjected to high temperatures and speeds. This specially formulated high performance motor bearing grease lubricant protects bearings from abrasive build up and ensures lubrication even at high loads.

| Beruplex HTA |

|

|---|---|

| Base Oil | Mineral oil |

| Thickener | Aluminium complex soap |

| Temp Range | -25°C to + 190°C |

BECHEM's Expertise for Textile Industry

BECHEM offers new generation speciality motor bearing grease designed for textile applications including spinning, weaving, processing and man made textiles that not only reduce maintenance costs but also boost productivity. BECHEM’s recommendations on effective lubrication engineering have enabled its customers to realise cost savings in replacement of spares, mitigate production losses and manpower costs.

BECHEM regularly conducts inhouse technical seminars and lubrication audits for customers with the intention of sharing knowledge on the importance of lubrication performance and its relation to cost savings.

Benefits for your Application

- Resistant to oxidation

- Super chemical and water resistant ability

- Extends re-greasing interval

- Comprehensive savings in man power cost

- No residue formation

- Extended service life

- Reduces temperature and power loss

- Excellent performance at, High speed, high temperatures and high loads

- Excellent corrosion protection properties

- Resistance to ingress of foreign particles in dusty environment

Lubricants for Textile Machine

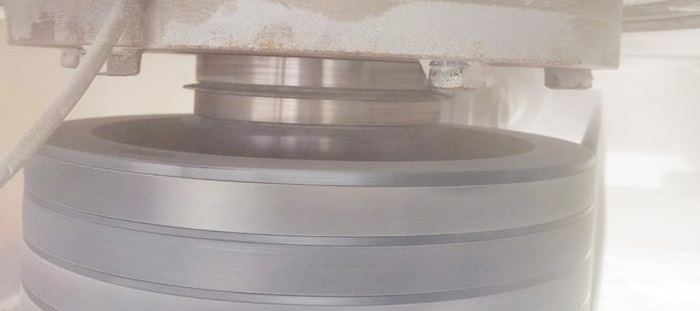

Draw Frame Top Roll-End Bushes

BECHEM’s range of lubricants for draw frame top roll-end bushes

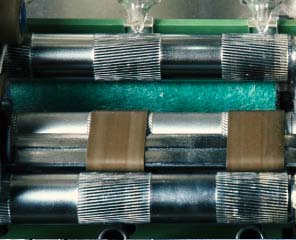

Ring Frame Bottom Fluted Rollers

BECHEM’s range of lubricants for ring frame bottom fluted rollers