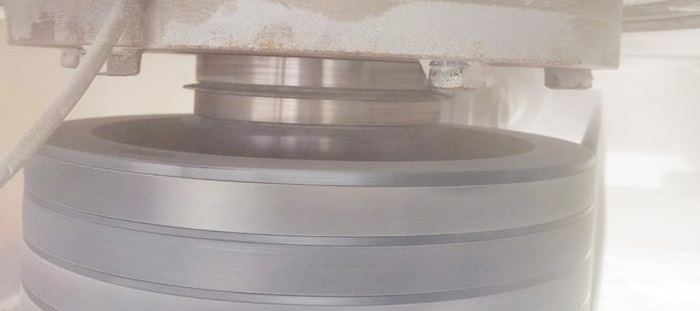

Continuous Caster Unit

Specialty Lubricants for Steel Plant

BECHEM Berutox M21 KN has good pumpability and does not harden or solidify when being pumped through centralized systems that are exposed to extreme thermal radiations.

Operational environment in a Continuous Caster unit is characterized by slow to medium rotational speeds, high temperatures and corrosive process water ingress. Spearheading the technology of large molecular poly-urea products, BECHEM has developed Berutox M21 KN for this demanding application.

BECHEM Berutox M21 KN by virtue of good sealing property extends life of the bearings by protecting the working area from water and abrasive foreign particles. The combination of high surface affinity (inherent to the molecular structure of the thickener-matrix) with well-balanced additives and high base oil viscosity offers a lubricant designed for extended service life and high performance in a thermally stressed operating environment.

BECHEM's range of lubricants for continuous caster unit

High temperature grease for long term lubrication, possessing excellent temperature consistency. This heavy duty grease has excellent pumpability for centralised systems. Provides good corrosion protection.

Applications: Berutox M21 KN is recommended for bearings and applications exposed to high temperatures and loads in continuous caster segments, cooling beds, conveyor systems, annealing and drying furnaces etc.

| Berutox M21 KN |

|

|---|---|

| Thickener | Polyurea |

| Base Oil | Mineral Oil |

| Temp Range °C | -20 to +180 |

Ceritol PSA 12 H has good pumping properties in the context of centralised lubrication systems exposed to thermal radiation. PSA 12 H possess good corrosion protection properties and provides good resistance to regular as well as aggressive water.

Applications: High temperature grease Ceritol PSA 12 H is recommended for plain and roller bearings exposed to thermal loads, bearings of dryer section and hot air fans in paper processing industry, guide rollers in slab and billet casters.

| BECHEM Ceritol PSA 12 H |

|

|---|---|

| Thickener | Special Polyurea |

| Base Oil | Mineral Oil |

| Temp Range °C | -20 to +160 |

BECHEM for Integrated Steel Plant

Conditions in steel manufacturing process pose tribological challenges due to extreme process temperatures, presence of corrosive cooling liquids, abrasive dust, shock-loads etc. Therefore the operational environment on a lubricant is very demanding and severe. The lubricant is primarily desired to provide a strong protective film with high degree of separation, be inert to entraining process fluids, resist tribo-corrosion and withstand high operating temperatures.

While operational breakdown costs are exponential, the lubrication technology to be employed requires careful consideration. BECHEM’s Berutox, Highlub and Beruplex range of specialty lubricants have been developed in order to surpass the demands in virtually all critical applications of an integrated steel plant.

BECHEM’s customised solutions complemented with unparalleled service help customers achieve higher productivity levels by mitigating machine downtime and extending equipment life.

Benefits for your Application

- Excellent consistency/temperature properties

- High corrosion protection

- Very good water resistance

- Very good wear protection

- Excellent pumpability

- Minimising of friction and wear

- Wide service temperature range

- Increased base oil viscosity

- Extreme pressure properties

You may also be interested in:

Latest Blog Updates

Enhancing operational reliability of Vertical shaft impactor (VSI) crushers with effective lubrication

Vertical shaft impactor (VSI) crushers, widely used in the construction and mining industries, are uniquely designed for high-impact crushing. The crushers are suitable for a wide range of applications including…

Challenges in lubrication of bearings exposed to high temperatures.

Case study on impact of high temperatures and loads on lubrication and therefore life of plummer block bearings in the drying range of a textile spinning mill. The drying range…

How effective lubrication of conveyor chain can impact process efficiency even at high temperatures?

Chains in drives and conveyors are highly stressed components in production lines as they typically endure harsh operating conditions like high temperatures, high load, dusty environments etc. High friction is…

Improving operational reliability of auger with synthetic food grade grease

Food and pharma processing industries adhere to a highly systematized process workflow having strict hygiene standards and food safety regulations. Methodical cleaning and regular sanitization of equipments are part of…