BECHEM India

High Performance Greases &

Oils

Pioneering the technology, BECHEM, has developed a vast array of high performance lubricants for critical applications in various industries such as Cement, Steel, Automotive, Textile, Food & Pharma, Sugar Processing and Metal Working Processes.

With its state-of-the-art production facility located at Bidadi near Bangalore, BECHEM India is one of the largest producer of specialty greases for industries in India.

High Performance

Industrial Lubricants

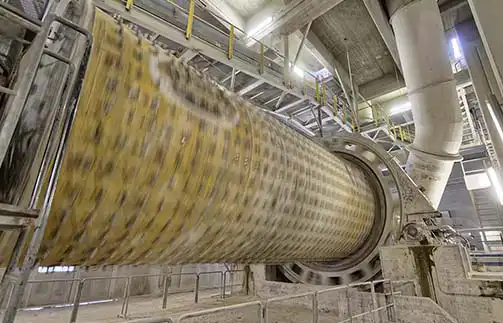

As a premier industrial lubricant manufacturer in India, BECHEM collaborates with machine manufacturers to create a wide range of specialty lubricants for the components and equipment found within integrated cement plants.

Read More

Read More

Read More

Read More

Read More

Read More

BECHEM

Speciality Lubricants

Read More

Read More

Additionally, BECHEM’s food grade range of lubricants are also ISO 21469 certified.

Read More

Read More

Read More

BECHEM'S RANGE

BECHEM, has developed a vast array of high performance lubricants for critical applications across industry segments. From high temperature greases for Steel mills to life lubricants for automotive components, BECHEM strives to create value for customer’s processes through consistent efficiency and environmentally responsible products.

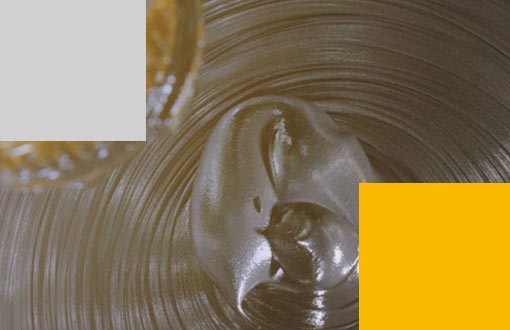

Lubricating Greases

Designed for critical applications, BECHEM’s special lubricating greases are recommended in heavy industries such as Steel, Cement, Mining, Power, Paper processing, Railways etc. as well as in vital high-tech sectors such as Automotive, Textile, Food, pharma & beverage processing etc.

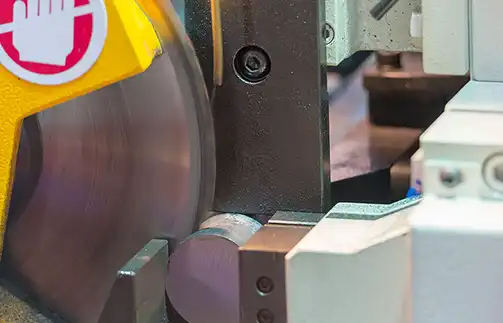

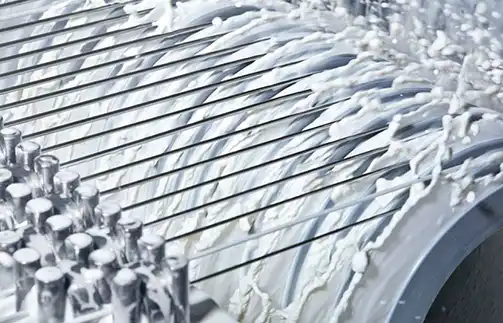

BECHEM’s extensive range of speciality oils and metal working fluids for industrial applications and metal working processes are developed with high quality base oils and advanced additive package.

BECHEM’s range of speciality fluids cover the entire spectrum of metal working processes from moderate machining to severe cutting operation to wire drawing and tube forming processes.

THE GERMAN

LUBRICATION

SPECIALIST

Support response: Median email response time of less than 3 hours.