How can lubricating oils impact process efficiency in forming processes?

October 15, 2022

How effective lubrication of conveyor chain can impact process efficiency even at high temperatures?

May 5, 2023Improving operational reliability of auger with synthetic food grade grease

Food and pharma processing industries adhere to a highly systematized process workflow having strict hygiene standards and food safety regulations. Methodical cleaning and regular sanitization of equipments are part of the standard operating procedures.

The mechanical components are exposed to water, steam, cleaning agents and acidic mediums as well as high and low operating temperatures. Effective lubrication of these mechanical components (such as chain drives, conveyor chains, roll support bearings, open gear drives etc.) is critical for continuous production run. Special food grade greases that can perform in challenging operating conditions are required to lubricate the mechanical equipment's in the food processing industry.

Development of food grade greases and oils are complex as ingredients and additives that would be typically used in regular performance lubricants cannot be considered as they do not meet the safety criteria set by the approval authorities.

Requirements of food grade greases and oils

Food-grade greases and oils need to provide efficient lubrication to mechanical components while contending the operating factors that are detrimental to the health of the lubricant.

- Provide resistance against water washout, oxidation when exposed to steam, water etc.

- Protect lubricated part from corrosion due to the acidic nature of food types being processed

- Protect frictional surfaces from fine food particles that can mix with lubricating film and cause wear of frictional surfaces

- Additionally as like other lubricants, food grade lubricants also need to perform regular functions such as: provide protection against wear, friction, dissipate heat, be compatible with rubber and other sealing materials and in some cases provide additional sealing effect

- Food grade products must also be physiologically inert, tasteless, odourless and certified.

Bechem’s wide range of food grade lubricants (oils and greases) certified by global standards of NSF and ISO 21469, are designed for critical applications in the food processing industry.

The below case study illustrates the impact of BECHEM NSF H1 food grade grease on the performance of ‘bearings’ in the auger at a food processing plant of a global brand.

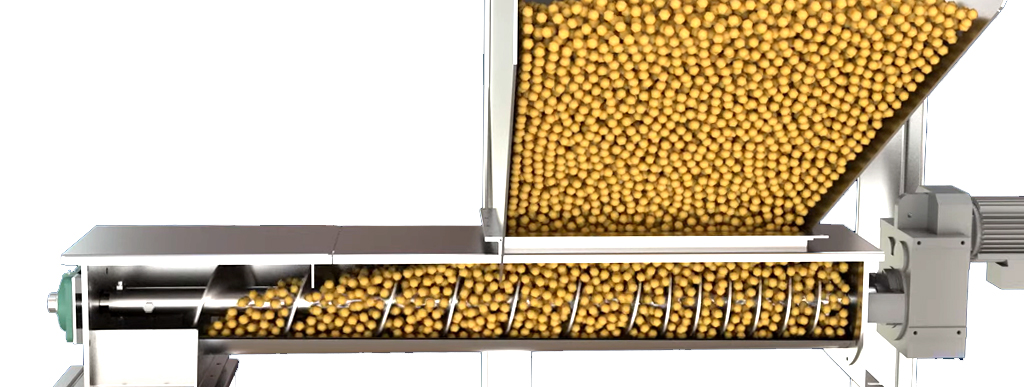

Customer: A reputed international brand in frozen food industry, well known for its nutritious and delicious assortment of fried food (potato based) products. The company with multiple production facilities in India and across the globe, follows stringent manufacturing protocols.

The maintenance team intended to improve reliability of the auger equipment by reducing frequent bearing failures which was creating unwanted downtime and associated costs.

Application: Auger is a mechanism that uses a rotating helical screw blade, within a tube to move and prepare the raw material. The auger within the plant was used for processing of steamed potatoes into paste by meshing and preparation

Bearing details:

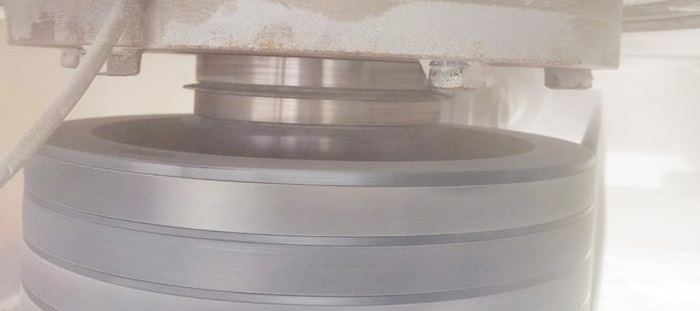

Bearing number: 3212, double row angular contact bearing

Operating conditions:

| Maximum Operating temperature: | 100 ˚C (recorded during operation) |

| Speed: | Medium |

| Load: | High combined load |

| Grease: | Synthetic food grade grease of Brand ‘X’ based on Aluminium complex soap |

| Re-lubrication frequency with ‘Brand X’ grease: | Every 15 days |

| Concern: | Regular failure of bearings in the auger leading to production downtime |

The BECHEM application engineering team had a chance to monitor the auger operation and noted the following operational parameters for the bearing,

- high combined load

- high operating temperature

- presence of steam

- possibility of water ingression into the bearing from the steamed potatoe

Considering these operational parameters, the Bechem team recommended a trial with food grade grease, Berulub FG H2 SL. During the trial period, Bechem Berulub FG H2 SL was applied to both ‘drive end’ (DE) and ‘non-drive end’ (NDE) bearings of the auger.

Why Berulub FG-H 2 SL

Berulub FG-H 2 SL , a high-performance food grade grease designed to enhance equipment reliability.

- Berulub FG H2 SL is developed with synthetic poly-alpha-olefin base oil, in which fully saturated hydro carbon offers high temperature resistance. (service temperature ranges from -45 °C to +160 °C)

- Fortified with anti-wear additives, Berulub FG H2 SL provides superior lubrication to frictional surfaces of the bearing under high load conditions

- Berulub FG H2 SL ensures good adhesion and sealing effect

- Homogenized with special calcium complex soap thickener, Berulub FG H2 SL

a. Provides excellent resistance to moisture, water, alkaline, acid disinfecting and cleaning agents

b. Special corrosion inhibitors prevent rust formation

- Berulub FG H2 SL is NSF H1 certified food grade bearing grease.

Trial observation:

-

- No bearing failure was observed during the trial period of 120 days.

- Re-lubrication was not required during the entire span of trial.

Consistent results were achieved with Berulub FG-H 2 SL resulting in,

-

- Increased equipment reliability and productivity by reducing downtime

- Extended relubrication interval

- Reduced maintenance activities

- Reduced operational costs

Result

Having observed performance of the product during the trial period with no breakdowns of the augur equipment, customer was happy to switch over to Berulub FG-H 2 SL. Further, the maintenance team recommended Berulub FG-H 2 SL for other applications including the potato peeler machine, freezer equipment.

For more details on Berulub FG-H 2 SLor sample of the product, write to us at [email protected]

Support response: Median email response time of less than 3 hours.