Safe, Biodegradable yet Cost Effective

Personnel deputed at the component cleaning section of a reputed cutting tool manufacturer were not too happy with the pungent smell of ‘mineral turpentine oil (MTO)’ that polluted the work environment.

While MTO provided just adequate cleaning, the Production team was on the lookout for a product that would provide better cleaning effect. Additionally, with bulk consumption and used oil output, the management was keen for a bio degradable alternative.

An effective cleaner that was physiologically harmless and eco friendly at the same time was need of the hour.

Background

The Customer, a well established Indian brand in manufacturing HSS cutting tools is the largest exporter in its category and also caters to the biggest names in Indian machining and automotive industry. With a comprehensive product range of over 50,000 tools, the company offers multiple options for various machining applications.

With production of close to 50 to 60k cutting tool units manufactured every day, the customer consumed tons of MTO as a part of the cleaning process during both the raw material preparation stage as well as in the final finishing stage.

During the raw material preparation stage, the cleaner was used to remove dirt, grease and other impurities from the metal bar prior to machining operations. Similarly, the finished component was cleaned off any oil residues or grinding dust after the final operations.

The customer had set up inline cleaning systems through dipping for initial raw material preparation and intermittent cleaning requirements. Ultrasonic machines were installed for the final finishing process.

The company had continued to use MTO as the inexpensive cleaning agent in all the cleaning processes. Personnel continuously exposed to the pungent odor of MTO experienced mild headaches and nausea at end of their shifts. The Management was keen to replace MTO that impacted work environment and employee morale.

Classed Mild Irritant:

While MTO has fairly low ‘acute toxicity’ that could impact through vapor inhalation or through continuous skin contact, continuous exposure could lead to drowsiness, nausea as well as severe irritant dermatitis or even chemical burns. Long term studies have shown continuous exposure could lead to chronic central nervous system effects impacting memory, concentration and irritability.

The Quality and Production team on the other hand were not too impressed with the finish of the cleaning with MTO. Traces of impurities and oil could still be seen on the components.

BECHEM’S Approach

At this juncture, BECHEM’s Product team pitched in with an advanced cleaning formulation that had proven better cleaning finish, was odorless as well as bio degradable. The Customer’s Production team promptly opened up for a trial of Beruclean S 4050 and measured the performance on following parameters,

- Cleaning impact

- Operator friendliness

- Odor

- Skin irritation or any other affect

- Evaporation rate

- Higher evaporation would increase consumption rate

- Too low would leave cleaner traces on components

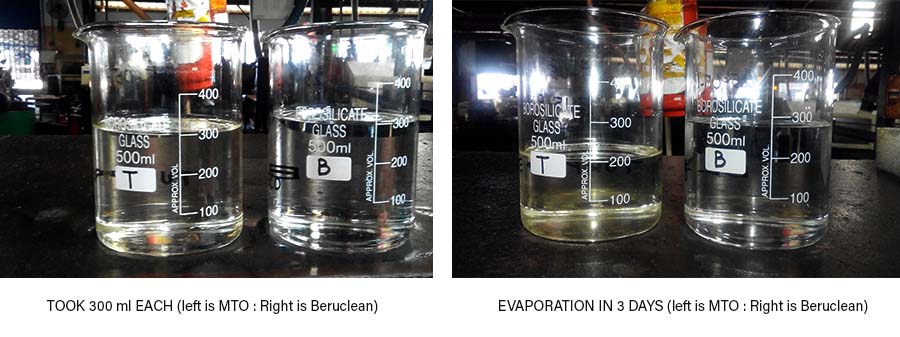

Evaporation Test :

To compare the performance of both the products, two 300 ml beakers were filled in with MTO and Beruclean S 4050 and left in ambient conditions (30 °C) for a period of 3 days. While there was marked loss of about 100 ml in the MTO beaker, the beaker with Beruclean S 4050 showed minimal loss of about 25 ml. During trials on one of the cleaning lines with Beruclean S 4050, it was recorded that there was a reduction of consumption by 67% compared to MTO.

At the same time, the Operators informed that Beruclean S 4050 dried off from the cutting tools within 3 minutes approximately. This evidence was recorded with temperatures hovering about 30 to 32°C at the shop floor.

Contamination Cleaning :

There was remarkable improvement in the cleaning effect with Beruclean S 4050. Hardened grease residues, high viscous oils and stubborn dirt that used to be stuck on carbide and HSS rods with MTO had been cleaned with Beruclean S 4050.

Operator Friendliness :

The company personnel were pleased to work with the odorless cleaning agent that did not give them a nauseating experience unlike MTO. The operators voted completely in favor of Beruclean S 4050.

QUICK COMPARISION

SL no | Properties | Mineral Turpentine Oil (MTO) | Beruclean S 4050 |

|---|---|---|---|

| 1 | Appearance | Colourless | Colourless |

| 2 | Type | Halogenated hydrocarbon | Non halogenated hydrocarbon |

| 3 | Biodegradable | No | Yes |

| 4 | Smell | Typical pungent hydrocarbon | Odorless |

| 5 | Operator friendliness | Long term exposure is not recommended | No impact |

| 6 | Flash point | 38°C | >50°C |

| 7 | Evaporation | Very High | Moderate |

| 8 | Cleaning effect with stubborn residues | Ineffective | Cleans, leaves no residues |

Key Takeaways

Beruclean S 4050 provides effective cleaning against stubborn residues such as grease, high viscous oils and impurities

With moderate evaporation rate, S 4050 reduces consumption when compared to MTO that has higher rate of evaporation

Beruclean S 4050 is operator friendly as it is odorless and has no adverse affect on operator health

Eco friendly as Beruclean S 4050 is biodegradable

Effective alternative against hazardous and flammable cleaning agents such as Trichloro ethylene (TCE), Diesel and Kerosene

Beruclean S 4050 is recommended for cleaning of ferrous and non-ferrous metals. Can also be used for cleaning of stone, marble, tiles, elastomer, plastics and textile materials

Beruclean S 4050 is recommended for automatic cleaning equipments, ultrasonic cleaning machines as well as by manual application

Beruclean S 4050 has good filterability. With good filteration system and process, the product is ready for re-use, depending on the level of contamination