Successive trials of Berusynth CF 250 at BOPP film manufacturers have proved excellent results. For more details of the chain oil and performance results, write to us at [email protected]

Impeccable Cleaning with Beruclean S 4050

July 28, 2020

7 Possible lubrication failure scenarios of industrial gear boxes due to prolonged stoppage

July 29, 2020Are you listening to your conveyor chains?

Peculiar noises and jerky movements from your conveyor chains are a signal that the lubrication set-up needs a relook.

Case Study Overview:

Berusynth CF 250 is a high performance chain oil based on synthetic ester developed for conveyor chains in plastic film stretching section of BOPP machine. The adhesive chain oil with superior penetrating properties and excellent wetting ability ensures optimal lubrication of friction partners in the chain. The special formulation of Berusynth CF 250 does not throw off or drip even at high speeds of the chain.

From solid granules to smooth thin films

In a typical plastic film manufacturing process, plastic polymers in granular form are melted and subsequently passed through multiple rolls as a woven film, intermittently cooling and heating, until the desired film thickness is achieved. The film stretching happens both length wise and also transversely. The transverse stretching involves clips that grasp the film during the intricate stretching process. Berusynth CF 250 is specifically designed for the chain conveyors of transverse direction orientation of polypropylene film stretching machines.

Performance and Reference

The BECHEM team had the opportunity to work with one of India’s leading manufacturer of BOPP films on optimising the lubrication consumption of conveyor chains at one of their facilities. With multiple manufacturing facilities and presence across the globe, the company supplies its high quality speciality films for packaging, lamination and labelling applications to top brands.

Details of the application

The high-speed conveyor chain is a critical equipment which needs to be efficiently lubricated to ensure break-down free film stretching operation. The BECHEM team in coordination with the Plant Maintenance personnel conducted a lubrication audit to observe lubrication requirements of the frictional partners in the conveyor chain.

Conveyor chain operational load and stress factors that need to be considered

Nature of movement, example:

sliding, rolling and impact. The frictional partners in the conveyor chain and guideways are subjected to high speed sliding movement

Relative speed

In modern machines, the chain speeds can be as high as 500 meters per minute.

Temperature:

The conveyor chain in a typical TDO (Transverse Direction Orienter) oven, stretching BOPP film can experience temperatures anywhere between 160 to 190°C depending on the zones.

Time:

Film stretching lines typically operate around the clock, 24 X 7 and 365 days a year unless a maintenance downtime is scheduled

Shock loading:

Remote possibility, only in case of film tear

Type of movement, example:

Intermittent or continuous: Continuous movement with very little start and stop

External contamination, example:

Presence of dust, solvent, acidic or alkaline chemical, water, humidity etc. No possibility of exposure to water or alkaline/acidic media, however mild film particles in case of film tear and remote possibility of floating dust particles.

Residue formation:

The oil should leave minimal residues as frequent cleaning of the chain links, pins and guide ways are not possible

Material compatibility:

The oil has to be compatible with Polypropylene material and in case of incidental contact with the film, should not form marks or wrinkles on the sheet. Additionally, components in the machinery are made from special materials such as phosphor bronze, copper and grades of steel. Some of these metals are sensitive to regular oils, resulting in undesired deposits over a period of time.

Life time expectation:

The chain oil operates on continuous loss type lubrication during regular operation. However, the lubricant should be able to provide efficient lubrication film. For example, a minimum of one hour between the friction partners in case of 30-micron film

Evaporation rate:

With temperatures hovering up to 190 °C in the TDO oven, the evaporation rate of the oil should be low to provide extended lubrication

Adhesion to lubricated surface:

Strong adhesive characteristics are required to withstand high speed sliding movement and resultant shearing forces

Corrosion protection:

Good corrosion protection properties will insulate frictional partners and associated components from corrosion.

Test Results: Berusynth CF 250

Evaporation

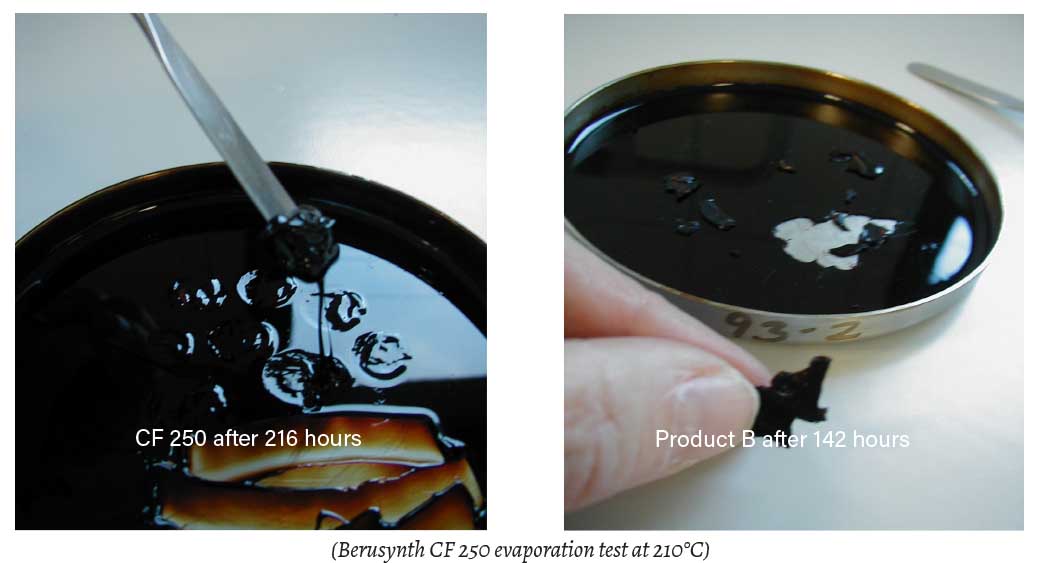

To study performance of the product at high temperatures a simple in house procedure was followed with sample of Berusynth CF 250 and another comparator chain oil. The samples were exposed to a temperature of about 210 °C until the oil dried off.

Berusynth CF 250 after 216 hours and Comparator sample after 142 hours

The comparator sample dried off by 142 hours with only dried residue available on the petri dish. The sample of Berusynth CF 250 was still good to perform at the same time period. Continuing the exposure, the chain oil finally turned sticky adhesive kind residue after about 216 hours.

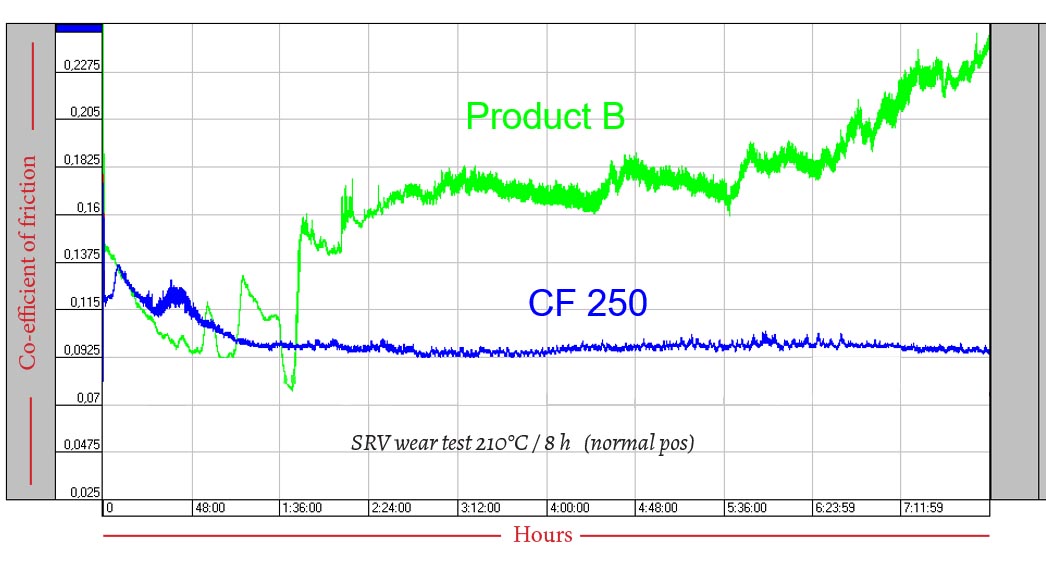

Lubrication Efficiency: SRV Test

To understand the load carrying abilities and lubricating effect of the oil under actual operating conditions of repetitive rubbing of the frictional surfaces, a SRV test was conducted for Berusynth CF 250 and two other comparators.

Operating temperature : 210°C | Duration: 8 hours

Frequency: 50 Hz | Load: 200 N

The lubrication film of Berusynth CF 250 withstands the test duration without any seizure for the complete 8 hours. However, the film of the comparator oil breaks down within 2 hours leading to seizure.

Corrosion Protection

Copper test strips were immersed for about 48 hours in samples of Berusynth CF 250 and comparator at elevated temperature of 210 °C to expedite the oil oxidation process. An oxidized layer was formed on the copper test strip of the comparator sample while there was negligible deposits on the strip immersed in CF 250.

Trial Recommendation and Result

With the lubrication audit complete and necessary tests conducted for compatibility, the product was trialed out in the TDO oven with the following parameters.

Film thickness: 30 microns | Chain speed: 240 mpm

Chain temperature at oven inlet: 123 °C (LH) and 130 °C (RH)

Chain temperature at oven outlet: 140 °C (LH) and 148 ° C (RH)

Trial Observation

- Smooth movement of chain without any abnormal noise

- Slight reduction in current consumption. Indicates, lower coefficient of friction due to better lubrication abilities of CF 250

- Smooth pumpability of oil through all pumping systems and nozzles

- Berusynth CF 250 leaves a thin oil film on the friction partners over a period of operation.

Observations: Long term usage

After a year’s continuous operation, the following observations were noted by the Maintenance team

- Smooth movement of chain without any abnormal noise

- Optimal consumption of the lubricant with no wear failure reported for chains, chain block and graphite blocks

- No residue formation on nozzles. With continuous operation, no change of nozzles for the period

- Oil compatible with Polypropylene sheet. No material compatibility issue reported