Chain links running dry is sure way to wear, noisy operation and breakdown. Cause for worry if you are restarting chain drives after prolonged downtime

Chain drives are used to transmit force and motion between parallel shafts. Many varieties of chains are in use like heavy duty roller chains, precision roller chains, flat top crate conveyors, duplex or triplex roller chains, inverted tooth or silent chains. While friction characteristics of these types of chains vary depending on construction and mounting position, there are common challenges in ensuring effective lubrication of drive chains. And special care should be taken while restarting chain drives after prolonged stoppage. Here is a quick check list of possible affects due to unplanned stoppage and remedies to ensure smooth and efficient operation of drive chains working in various operating conditions.

The chain drives in industry are classified as follows:

Chain drives operating at room temperature

Chain drives operating at high temperatures (temperature of 80°C and more)

Chain drives operating at dusty environments

Chain drives operating at humid, chemical and water environments

Possible affects due to prolonged stoppage

Chains operating at room temperature, dusty, humid, water and chemical environments

Oxidation of lubricant used due to prolonged idle time

Formation of oxidative by products which are usually higher in molecular weight and hence forming thick deposits

Dust accumulation on top of chains which in turn will form a paste in combination with the lubricant.

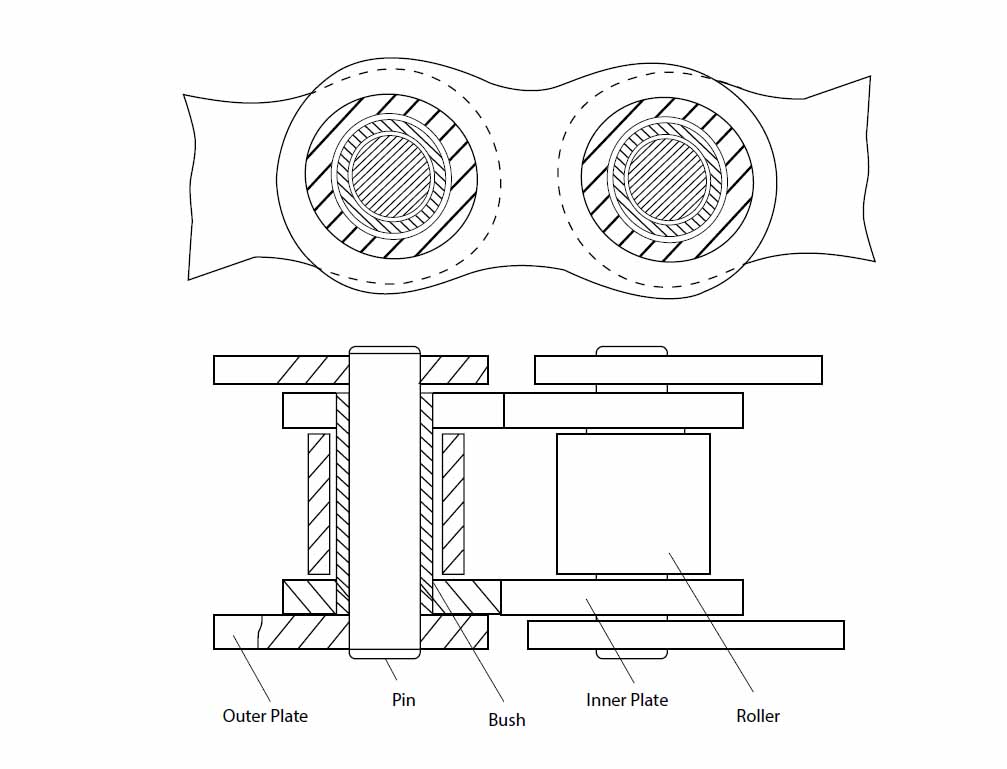

Entry of abrasive dust particles into the outer plate / pin and inner plate / bush clearances. This can result in abrasive wear

Corrosion within precision parts of the chain due to chemical and water attack.

Restarting after prolonged stoppage

Clean the accumulated dust, pasty dust (mix of lubricant and dust) and oxidised lubricant with a lint free cloth. Use fast evaporating solvent like Petrol if necessary

Check for elongation of chain in comparison with original length. If the extension is above 5 % of original length, remove links accordingly or replace chain

Check for corrosion on chains. If severe corrosion is noticed replace the chain. In case of mild corrosion, clean the same with a cleaner

Use specially designed high viscosity chain lubricant which has good adhesion properties and anti-wear properties

If chain is manually lubricated, apply oil from oil can at a rate of four to ten drops per minute (depending on the pitch of the chain) in the gap between the inner and outer plates

Allow thirty minutes time for the lubricant to penetrate into the deep friction partner (pin, bush, roller, outer plate and inner plates) before restarting the chain

If the chain is passing through a dip system (force feed splash lubrication), check for cleanliness of the lubricant sump. If contaminated or oxidised, replace oil sump with fresh oil

During initial phase of running check for slackness, noise, improper engagement with pinion and sprocket. If the system displays any of these symptoms, do the necessary mechanical corrections before the chain is put into regular use

Possible affects due to prolonged stoppage

Chains operating at high temperatures (above 80°C ), dusty and chemical environment

Reduction in base oil viscosity of the lubricant due to high temperature exposure, resulting in oil bleed from the lubrication zone

Chances of dry running, due to low presence of lubricant in the friction zone, which can result in increased wear

Evaporation of base oil from the chain due to high temperature resulting in lubricant starvation

Oxidation of the oil and formation of lacquer like hard adhering residues on the chain links

In case of centralised lubrication system, nozzle direction can get off located resulting in oil spray to the non-friction areas in the chain

Corrosion on chains exposed to chemical attack

Accumulation of dust from the environment resulting in abrasive wear

Restarting after prolonged stoppage

Clean old residues of lubricant, Oxidation deposits and dust using a lint free cloth. If necessary, use a fast evaporating solvent to remove the residues

Check for presence of oil on the chain links with a tissue paper impression. If found dry, apply a liberal coating of high temperature chain oil fortified with anti-wear and adhesion improvers

In case of centralised lubrication system, check for proper system pressure and spray pattern. Conduct the necessary corrections to ensure required spray pattern

Check the orientation of the nozzles to ensure that the Oil and air mist is directly reaching the friction partners. Adjust the nozzle orientation as necessary

Clean mild corrosion using cleaner, If severely corroded, replace the chain

Machine Restart Guideline

General guideline to check condition of lubricant (greases and oils) in machines after prolonged stoppage to ensure maximum performance and avoid wear damage

Do not start any bearing in full load and maximum speed condition immediately after extended stoppage period. If possible, run the bearings under no load condition for one hour, before increasing the load and speed in steps

Where ever dynamic or static seals are provided in the equipment, check them for hardening and brittleness. Change the seals if they have become too hard or brittle

Equipments which are prone for mis-alignment as per maintenance records, should be checked for alignment before restarting them

All grease guns and grease pumping equipments need to be recalibrated, before being put to use. Grease in containers to be checked for oil separation and stirred with a clean rod wherever necessary

All oil storage drums should be checked for sedimentation and cleanliness. Thoroughly shake oil drums/ oil cans before taking oil for lubrication

For rust removal of machine parts such as housing, bearings, gears etc, Beruclean 3849 is recommended

The recommendations are based on our books of experience and available knowledge at the time of release. The general guidelines are to check condition of lubricant (greases and oils) in machines due to unplanned stoppage that can be affected due to a combination of known and unknown factors including natural ageing, environmental impact or contamination by external impurities. For further reference and practices specific to the equipment, we suggest you to follow the machine manual or contact the Service team. This information is intended as a guide and does not necessarily represent a marketing specification. To address your concerns, please contact our Engineering Team on +91 80 66900800 / +91 9379917484

Machine Restart Guideline for Bearing

Avoid bearing failure while restarting machines after prolonged stoppage. Restarting machines without priming after prolonged stoppage can have adverse effect on the components and land you in further downtime. While there is a vast range of bearings suited for every application based on speed, load and alignment, optimal lubrication is a common yet critical requirement for efficient performance. Here is a list of possible scenarios that can adversely affect bearing performance due to lubricant starvation and remedies to ideally prep the machine before restart.

Machine Restart Guideline for Industrial Gearbox

7 Possible lubrication failure scenarios of industrial gear boxes due to prolonged stoppage. Condition of the oil prior to restarting a gearbox after a prolonged or unplanned stoppage would make the difference between smooth operation and unwanted wear as well as surge in temperature. Here is a list of possible scenarios that can adversely affect performance output of the gear box due to lubricant starvation and remedies to ideally prep the gearbox before restart. Condition of the oil is an indicator of the long-term reliability of the gear box.