Enhancing machining efficiency with high performance minimal quantity lubricants

May 24, 2025Productivity boost with increase in bearing life and re-lubrication interval with Berutemp PM 2-220 EP

Stand-out lubrication performance of polyurea grease, Berutemp PM 2-220 EP in increasing life of pellet mill bearing and thereby better mill utilization

Pellet machines play a crucial role in manufacturing of poultry feed. Operating under demanding conditions that include extreme temperatures, high pressure, and frequent exposure to contaminants, the machinery experience significant strain, especially the bearings, which are vital to smooth operations. The performance of bearings are directly impacted by their lubrication. Incase of ineffective lubrication and breakdown of lubrication film, friction between the moving components increase, leading to rise in temperature, accelerated wear and eventual bearing failure.

Additionally with rising awareness around food safety, use of food-grade lubricants has become a key consideration in modern poultry feed mills. These specialized lubricants are formulated to withstand heavy loads and extreme temperatures, ensuring that equipment operates smoothly under the toughest conditions.

Pellet Feed Mill

Below case study demonstrates the importance of reliability-centred maintenance approach with lubrication in the context of animal feed mill.

Customer: A reputed Indian manufacturer of high-quality poultry feed supplement with supplies to a wide consumer base across the country.

Operational parameters

|

Application |

Pellet Mill Bearings |

|

No of bearings |

4 |

|

Bearing type |

Taper roller bearing no. 32220 |

|

Bearing rotational speed |

288 RPM |

|

Load on bearing |

High |

|

Bearing temperature |

90℃ |

|

Re-greasing frequency |

Once in 12 hours |

|

Bearing life with brand ‘Y’ grease |

3 months |

Customer was using lithium based extreme pressure grease of a reputed brand ‘Y’. However, the maintenance team aimed to reduce the operating temperature of bearings and reduce re-lubrication frequency, thereby reducing maintenance shutdowns for lubrication.

Closely observing the operating conditions, Bechem team recommended trial with Berutemp PM2-220 EP, long-life, extreme pressure grease specifically formulated for high-speed, heavily loaded bearings exposed to high temperatures

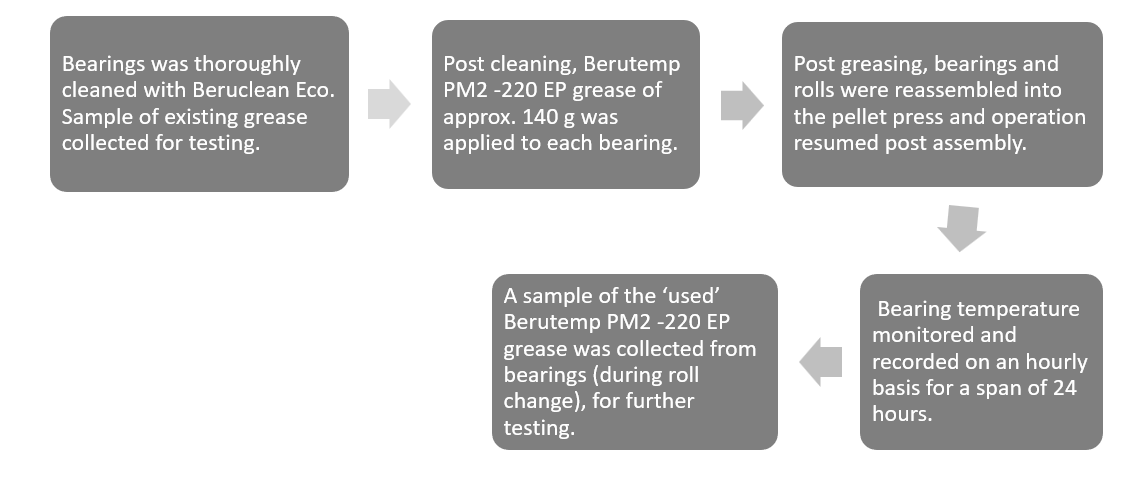

Trial method:

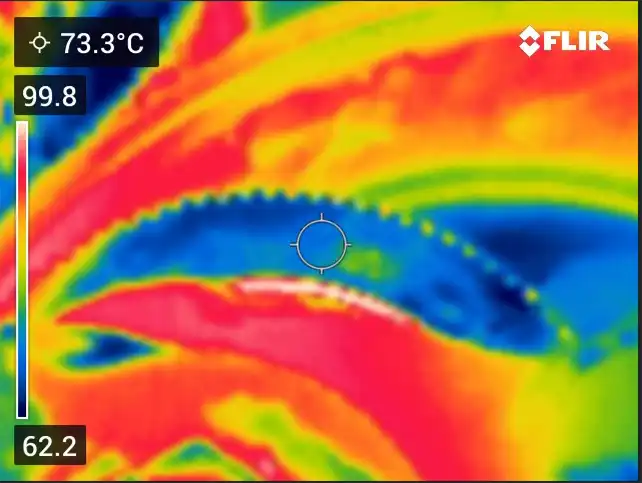

Temperature of the bearing recorded with grease of brand ‘Y’

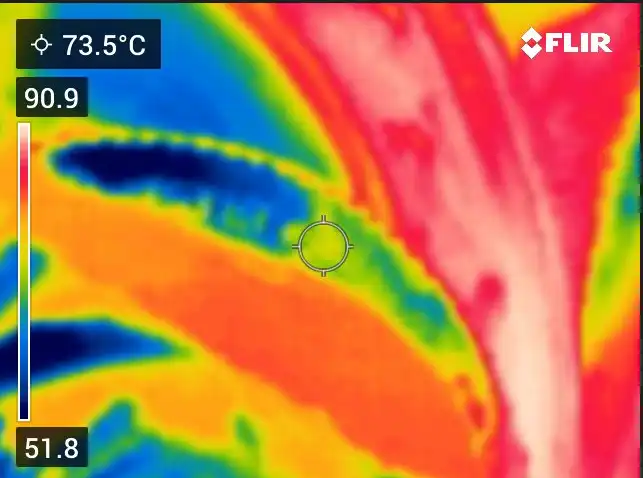

Temperature of the bearing recorded with Berutemp PM 2 -220 EP

Trial summary :

Why choose Berutemp PM 2-220 EP?

- Maximized equipment longevity: Berutemp PM 2-220 EP offers exceptional thermal stability, ensuring machinery operates efficiently under extreme temperatures. Optimum base oil viscosity ensures, Berutemp PM 2-220 EP maintains its lubrication efficiency until the intended operational hours.

- Reduced downtime and lower maintenance Costs: Fortified with anti-wear additives, Berutemp PM 2-220 EP ensures consistent lubrication film on bearing surfaces, even under high load conditions. Longer lubrication service life ensures extended lubrication intervals, reducing the need production downtime for lubrication maintenance.

- Enhanced protection against corrosion: Developed with poly urea-based thickener, Berutemp PM 2-220 EP provides outstanding resistance to moisture and organic materials, offering superior corrosion protection, prolonging bearing life.

- Reliable performance under high-speed operations: Berutemp PM 2-220 EP offers excellent shear stability, maintaining consistent lubricating properties under high shear forces, hence, ideal for high-speed operations.

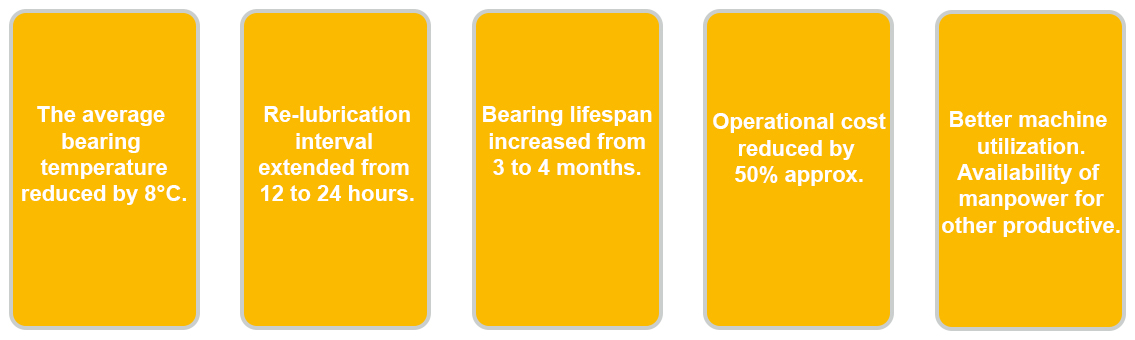

Result :

Observing the performance of Berutemp PM 2-220 EP in extending bearing lifespan and doubling the re-lubrication interval, the customer switched to Berutemp PM 2-220 EP.

For more information on Berutemp PM 2-220 EP or BECHEM’s range of speciality lubricants and cleaners for feed mill industry, drop us a message with the below query form.

Support response: Median email response time of less than 3 hours.