Best in class lubrication efficiency for circular knitting machines with BECHEM Staroil KNT 32

June 7, 2022

BECHEM Staroil KNT: High Performance Knitting oil for Longer Needle Life

June 7, 2022Consistent Performance with Staroil KNT 32

Every drop counts. Journal of 3-month trial with Staroil KNT 32, resulting in reduction of machine operating temperatures and oil consumption

Customer: Manufacturer of knit fabric and garments located in Tirupur, in the state of Tamil Nadu, India with complete supplies to export market.

Process details

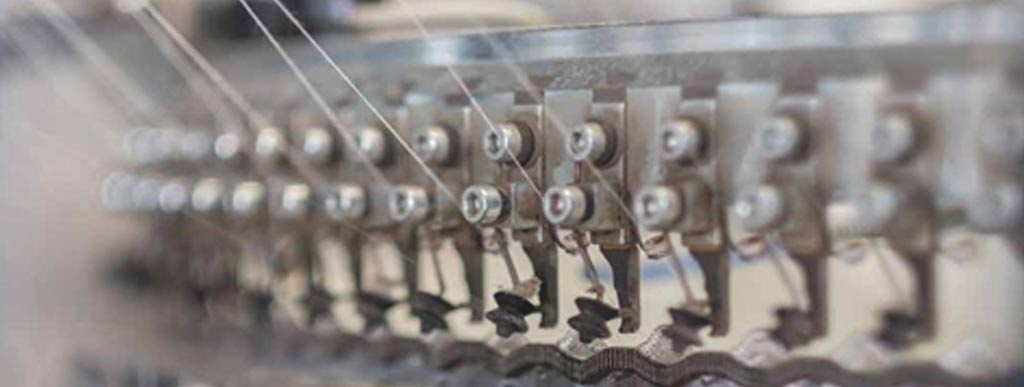

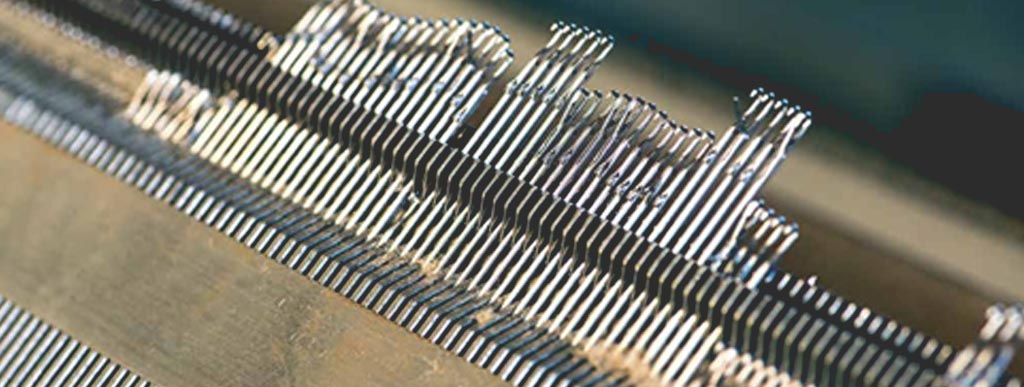

Application: Circular knitting machine

Machine OE: Reputed German brand with history of developing advanced knitting machines

Material to be knit: Cotton grey

RPM (revolutions per minute): 25.4 (Avg.)

Existing knitting oil: Brand K oil - M plus

Knitting oil consumption with existing product: 700 ml/da

Trial procedure observed

Two identical knitting machines numbered, 8 and 9 with similar processes were selected for the trial. Machine no.8 was run with the existing knitting oil, ‘Brand K oil M Plus’ while ‘machine no. 9’ was run with BECHEM Staroil KNT 32.

Performance of both the products on the respective machines was observed for a period of 3 months with temperature monitored at key points (needle cam, needle cylinder and sinker cam) of the knitting bed.

Average temperature readings

|

Section |

Temperature points |

Avg. temperature readings in °C | |

| Machine no. 8 with Brand K oil M Plus |

Machine no. 9 with BECHEM Staroil KNT 32 |

||

|

Needle cylinder |

1 | 67 | 65 |

| 2 | 65 | 63 | |

| 3 | 67 | 64 | |

| 4 | 65 | 61 | |

| 5 | 64 | 62 | |

|

Needle cam |

1 | 64 | 62 |

| 2 | 66 | 63 | |

| 3 | 68 | 65 | |

| 4 | 66 | 63 | |

| 5 | 66 | 64 | |

|

Sinker cam |

1 | 58 | 54 |

| 2 | 56 | 53 | |

| 3 | 55 | 52 | |

| 4 | 58 | 54 | |

| 5 | 57 |

53 |

|

- Average oil consumption in machine no. 8 with ‘Brand K oil M plus’: 700 ml/day

- Average oil consumption in machine no. 9 with BECHEM Staroil KNT 32: 550 ml/day

Trial results

● Reduction in temperature: Average reduction in temperature of about 2.6 °C in needle cam and cylinder section was observed with BECHEM Staroil KNT 32 over ‘Brand K oil M plus’. The average reduction was higher at about 3.6 °C in the sinker cam section with BECHEM Staroil KNT 32.

● 21% reduction in oil consumption was observed with BECHEM Staroil KNT 32 (550 ml per day) against ‘Brand K Oil M Plus’ (700 ml per day).

● At a reduction of 150 ml per day, the Customer was able to reduce about 54 liters in a single machine in the 3-month trial period with BECHEM Staroil KNT 32.

● 100% QC Approved : Demonstrating the washable property of Staroil KNT 32, the material processed during the trial stage was approved by Quality Control Department.

Based on the trial result, the customer shifted over to BECHEM Staroil KNT 32 for all the circular knitting machines in his plant.

Support response: Median email response time of less than 3 hours.